- Home

- About Us

- Blog

- Services

- Equipment

- Online Testing

- Offline Testing

- Partial-Discharge

- CPC 100 Multifuncational Switchyard

- Vlf Tan Delta Measurement

- Current Signature Analysis

- Relay Measurement

- CT Measurement

- SFRA Measurement

- Moisture Analysis by PDS & PDC

- Turns-Ratio-Measurement

- Winding Resistance Measurement

- OLTC-DCRM-Measurements

- Frequency Response stray Losses

- Circuit Breaker Analyzer & DCRM Test

- Circuit Breaker Timer

- Contact Resistance Meters

- Particle Count Tester-Pamas

- TRAX Multifunctional switchyard Diagnostic Test

- TESTRANO-600

- Surge Tester-jabbals

- Circuit Breaker Analyzer

- Gallery

- Careers

- Contact Us

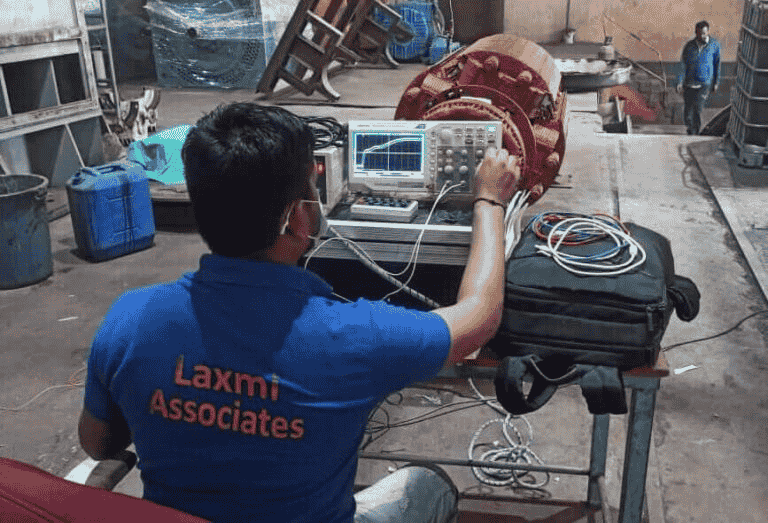

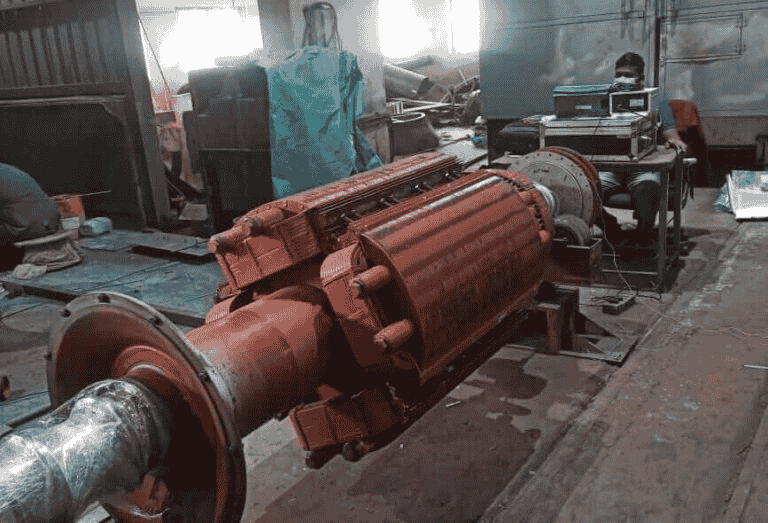

GENERATOR TESTING SERVICES

Testing of Generator

Generator Testing is the procedure of analysing the functionality of an electrical generator. Generators mainly convert mechanical energy into electrical energy in various settings, like power plants, industrial facilities, and backup power systems.

Since generators play a vital role in the supply of electricity, proper maintenance and testing of generators are mandatory. This article will help you understand the fundamentals of generator testing and its benefits.

Ways of Generator testing

The different methods of testing a generator are :

- Load bank testing- Load bank testing verifies that all the primary components of the generator are in good working condition. It ensures that a generator is reliable during an emergency, thus being the most critical test conducted.

- Online Stator Winding Partial Discharge(PD) – It helps to detect the primary reasons for stator winding failure. PD are tiny electric sparks in the electrical insulation stator windings( a stator is a stationary part of several coils).

- Online Generator Condition Monitoring- The Generator Condition Monitor (GCM) is a monitor which focuses on the thermal particulate that is the problem of the generator related to heat and dust particles.

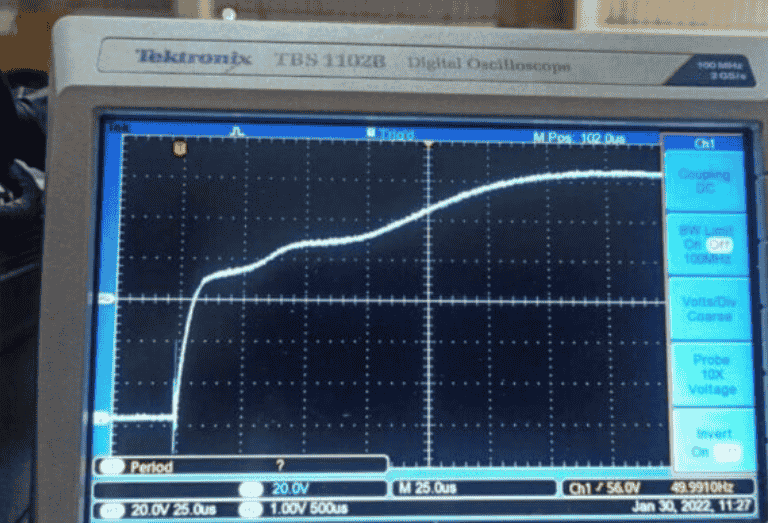

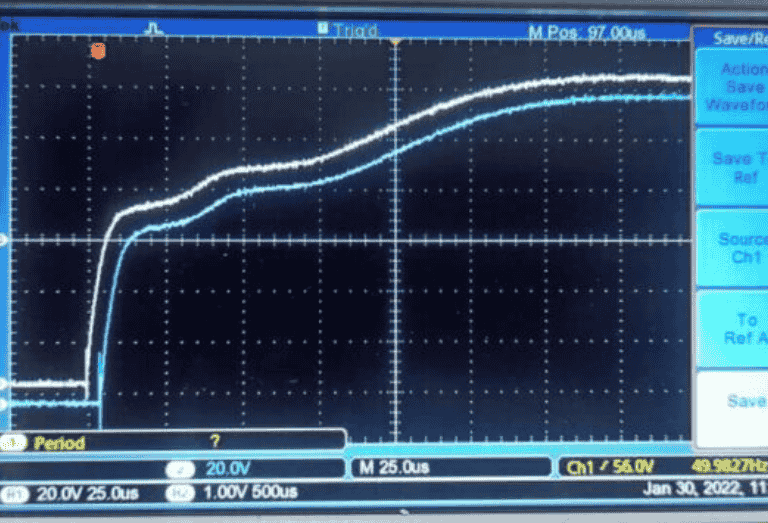

- DC Insulation Resistance (IR) and Polarisation Index(PI)- The Insulation Resistance test measures the resistance of the electrical insulation. The low value of Polarisation Index indicates that the winding may have been contaminated.

- Dielectric Discharge (DD) and Step Voltage (SV)- The Dielectric Discharge Test and the Step Voltage Test are incredibly convenient tools that show the indicator levels of the absorbed moisture, dirt, and over-stressed insulators.

- AC Power Factor and Capacitance- The practice of Power factor and Capacitance applies to operating stator coils( stationary part with coils) of electrical equipment.

- Online Test for Rotor Winding Integrity- The test of Rotor (rotating) winding integrity is implemented to prevent possible defects and repair any defects already in place.

- Generator Excitation Generator Testing- Excitation system provides current to the rotor winding (rotating part of the machine). So testing the excitation system can remove costly and unsafe operations.

- Instrumentation- It is vital to trust the instruments on your generator system. Therefore, regular testing of instruments in the generator should be done.

- EL CID and Ring Flux test- This process checks for core damage. Electromagnetic Core Imperfection Detection (EL CID) is used to check the integrity of the insulation for cores of generators.

- Visual Inspection- Visual or eye inspection may be helpful in some instances of generator testing. Since certain imperfections or problems can be detected by human eyes.

Testing of different kinds of Generators

- Emergency Generator Testing- An emergency generator is a standby generator or backup electrical system that operates automatically. Different generators are tested in different ways like, the ship’s emergency generator test is done weekly or monthly to ensure the battery mode,hydraulic starts and automatic starts works efficiently.

- Standard tests for Diesel Generators- Diesel generators are the most widely used generators in industries and factories.

- The standard tests performed in industrial generators are: Type tests like Governor tests to check the hang, cold and hot starting tests etc, Routine tests, and Ancillary Plant tests.

Conclusion

Generators are used in various crucial places, leaving no room for errors in their operation. Since problems discovered early can be significantly less expensive and prevent issues in the future, generator testing assures that the generator works appropriately when you need it the most.

Generator testing can help ensure the generator operates safely, efficiently, and reliably. It confirms the quality of the generator and validates the insulation systems so that the generator can meet the electrical needs of the system it serves.

FAQs

Ways of Generator testing

1. Why is it important to test generators?

Regular testing ensures that it is in good working order and will be ready if the main power goes out and extends the life of generators too.

2. What are some common tests performed on generators?

Common tests for generators include insulation resistance tests, winding resistance voltage and frequency testing, load bank testing etc.

3. How often should generators be tested?

Regular testing ensures that it is in good working order and will be ready if the main power goes out and extends the life of generators too.

4. Who can perform generator testing?

Depending on the type of testing required, various professionals like electrical engineers, technicians etc., may be involved. However, one common thing among all will be expertise and adequate training.

5. What are the benefits of testing generators?

The benefits of testing generators are detecting potential problems, improved performance, enhanced safety and longevity, etc. It also helps save on unwanted repair costs in future.

6. What is Wet stacking?

When the diesel engine runs below its designed operating temperature for extended periods, unburned fuel is exhausted and observed as wetness in the exhaust system.This phenomenon occuring due to the prolonged usage of a generator on no load is known as “wet stacking”.

7. How to prevent wet stacking?

The solution is to run the engine on at least 40% of full load for 60 minutes. The exhaust will get hot enough to burn off the deposits, like the Pyrolytic cleaning function on your kitchen oven or stove.

8. What are the different kinds of generators used in industries?

Depending on the type of testing required, various professionals like electrical engineers, technicians etc., may be involved. However, one common thing among all will be expertise and adequate training.

There are three main types of generators:

- Portable generators

- Inverter Generator

- Standby Generator